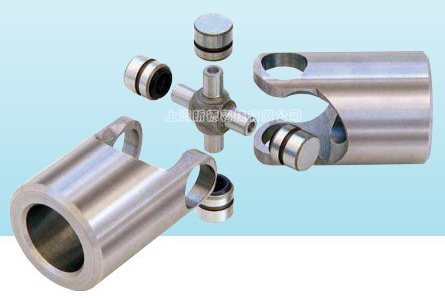

When preparing to assemble a cross-shafted universal joint, there are several crucial steps and precautions that cannot be overlooked. After all, as a vital component in the drivetrain system, the assembly quality of the universal joint directly impacts the vehicle's driving performance and service life. Below, Xinde will elaborate on three key issues to pay attention to when assembling a cross-shafted universal joint, ensuring a smooth assembly process and maximizing the joint's performance.

When assembling a cross-shafted universal joint, meticulously follow these three important precautions:

Firstly, ensure all parts are thoroughly cleaned in clean washing oil and then dried. After this step, carefully inspect the surfaces of key components such as the cross-shaft journal, bearings, oil seals, and thrust washers (some vehicle models may not have this washer). These surfaces should be smooth and flawless, free from any cracks, wear, or other defects, to ensure the smooth operation and long-term durability of the universal joint.

When installing the cross-shaft into the universal joint yoke, pay special attention to one detail: ensure that the side of the cross-shaft equipped with the grease fitting faces the driveshaft. This design facilitates future maintenance by allowing easy lubrication when needed, thereby ensuring good lubrication and smooth operation of the universal joint.

For universal joints equipped with thrust washers, during assembly, place the washer accurately between the inner end face of the bearing housing and the end face of the cross-shaft head. After tightening the bearing cap's securing bolts, carefully check the rotation of the universal joint yoke on the cross-shaft. It should rotate freely, with no sticking or axial clearance felt in the cross-shaft. If axial clearance is detected, promptly install thrust washers of appropriate thickness on the end faces of the two symmetrical journals or replace them with thicker thrust washers for adjustment. However, ensure that the thicknesses of the washers on both sides are equal to maintain the balance of the driveshaft and ensure its stable and reliable operation.

Assembling a cross-shafted universal joint may seem simple, but it involves many technical details. Statistics show that over 60% of early failures are due to improper assembly. It is recommended that beginners follow the original manufacturer's repair manual step-by-step during their first installation and take photos of critical steps for documentation. If unsure about any step, please promptly contact the original manufacturer's technical support.

Contact: Tina Lau

Phone: 13371933299

Tel: 021-34150570

Email: 13371933299@126.com

Add: No.388,Doushi road,Zhuanqiao town,Minhang district, Shanghai