Excessive Vibration in Chain Couplings? 6 Major Causes and Professional Solutions

Are these signs appearing on your production line? Persistent abnormal noise in the chain coupling area, increased equipment vibration, and frequent bearing damage? Excessive vibration not only reduces transmission efficiency but also serves as a red alert for equipment failure! This article, drawing on Xinde's industry experience and technical specifications, summarizes the six core causes of excessive vibration in chain couplings and provides targeted solutions for each.

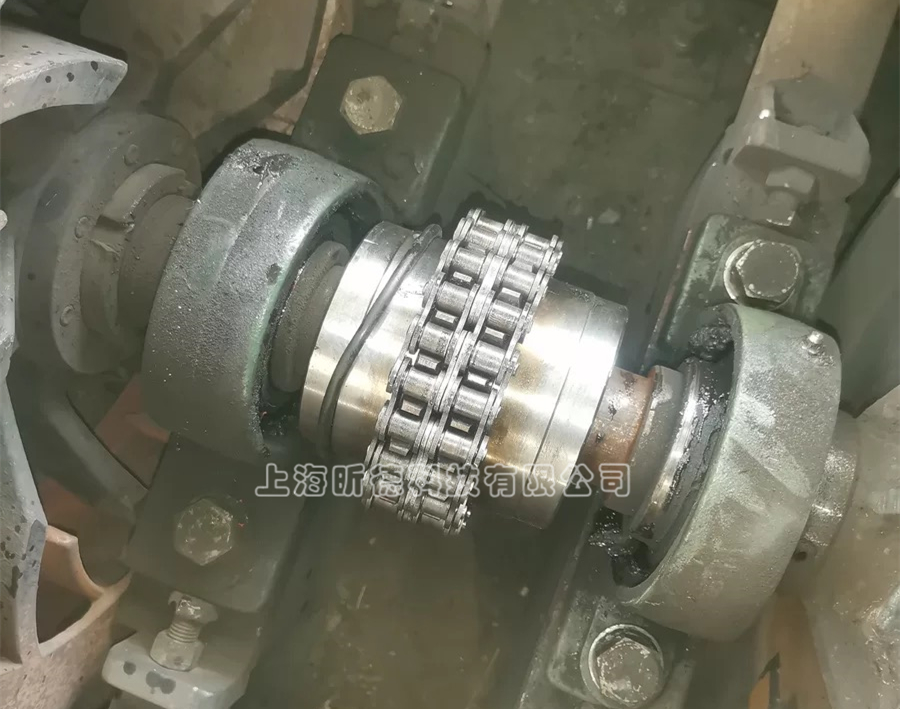

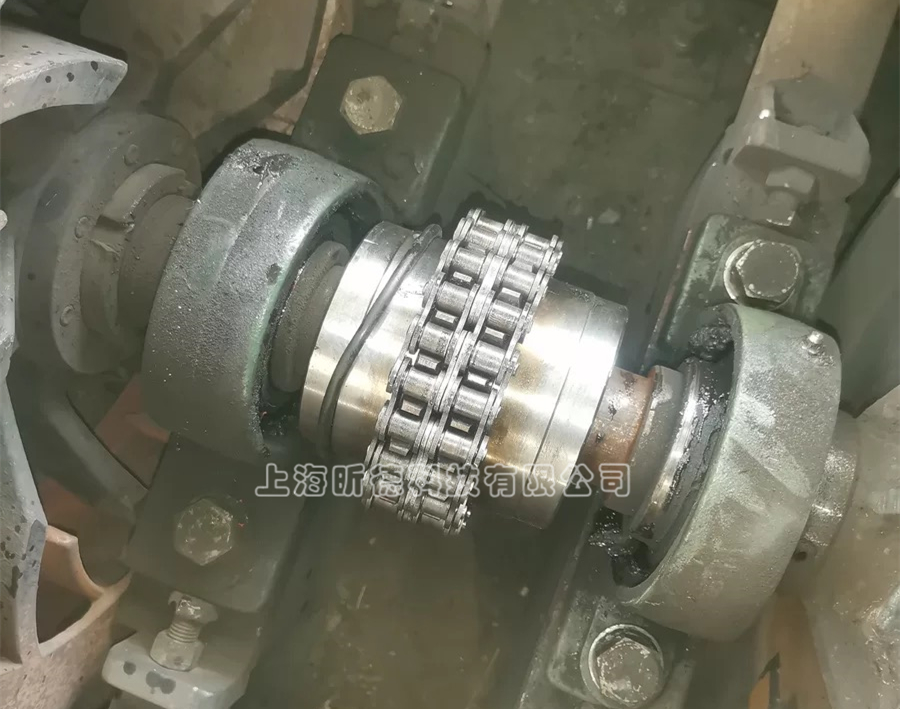

I. Excessive Wear on Chains or Sprockets

Cause Analysis: After long-term operation, chain links may experience pitch elongation due to wear, and sprocket tooth surfaces may also show signs of wear or deformation. This wear disrupts the meshing accuracy between the chain and sprocket, triggering periodic vibrations.

Solutions:

-

Regularly inspect the wear on chains and sprockets, measuring chain link pitch and sprocket tooth profiles.

-

If the chain pitch elongation exceeds 3% or sprocket tooth surface wear is severe, promptly replace the chain or sprocket.

-

Opt for chain materials with enhanced wear resistance (such as double-strand roller chains) to extend service life.

II. Misalignment of Two Shafts Beyond Tolerance

Cause Analysis: Misalignment of the two shaft centerlines during installation or shaft axis deviation due to loosening during equipment operation can generate additional bending moments, causing vibrations.

Solutions:

-

Use a laser alignment tool or dial indicator to measure the misalignment of the two shafts, ensuring parallel deviation ≤ 0.1mm/m and angular deviation ≤ 0.5°.

-

Adjust the coupling installation position or correct axis deviations using adjustable center distance devices.

-

Regularly tighten coupling bolts to prevent loosening during operation.

III. Improper Chain Tension

Cause Analysis: An overly loose chain can lead to poor meshing and shuddering, while an overly tight chain increases friction and exacerbates vibrations.

Solutions:

-

Use a chain tension gauge to measure the sag on the loose side, which should be 2% of the center distance for horizontal drives.

-

Adjust the tensioner or connecting bolts to achieve the chain tension specified by the equipment.

-

Avoid overloading the equipment to reduce elastic deformation of the chain.

IV. Poor Lubrication or Foreign Object Intrusion

Cause Analysis: Insufficient lubrication on the chain can cause dry friction, while foreign object intrusion may jam chain links, triggering abnormal vibrations.

Solutions:

-

Regularly clean oil and impurities from the chain surface to ensure smooth rotation of chain links.

-

Use high-temperature-resistant, wear-resistant grease and lubricate according to the equipment manual.

-

Install protective covers to prevent the intrusion of dust, metal filings, and other foreign objects.

V. Equipment Overloading

Cause Analysis: When the design torque of the chain coupling is lower than the actual load, it can cause slippage between the chain and sprocket, triggering vibrations.

Solutions:

-

Calculate the equipment load and select a chain coupling with a rated torque 1.5 times greater than the actual demand.

-

Install a torque monitor to continuously monitor load changes and prevent overloading.

-

Optimize the transmission system to reduce the impact of shock loads on the chain coupling.

VI. Unstable Coupling Installation Foundation

Cause Analysis: Loose equipment bases or uneven ground can cause additional vibrations during coupling operation.

Solutions:

-

Check the fixing bolts on the equipment base to ensure they are not loose.

-

Level the ground or reinforce the base support structure.

-

Install vibration-damping pads under the coupling to absorb vibration energy.

The issue of excessive vibration in chain couplings involves multiple aspects such as design, installation, and maintenance. Implementing measures such as regular inspections, precise alignment, proper tensioning, and optimized lubrication can effectively reduce vibration risks and extend equipment service life. If the above solutions fail to resolve the issue or if the vibration problem persists, it is recommended to contact professional technicians for vibration spectrum analysis to determine more precise fault causes.